FIVE TRENDS IN CONCRETE TECHNOLOGY

FIVE TRENDS IN CONCRETE TECHNOLOGY

There has been an increase in construction activities in the 21st century. Concrete has been widely utilized in constructing many structural components because it is durable and gains strength. Due to the rising need to maintain the sustainability of concrete materials in the construction industry, many researchers are geared towards technological advancements.

Previously, the success of concrete producers was mainly dependent on the assets; those who owned the greatest assets dominated the market. Recently, this has been shifting, and technology is now the dominant factor. Through technology, there is a reduction of the operating costs in the entire supply chain.

Technological advancements are now enabling concrete contractors to develop newer technology, thus increasing the construction process efficiency. Therefore, the construction team can decide on the best method among the technology trends to incorporate into their design and construction processes. There are increasing trends in concrete technology, but this article will focus on the five major trends tried and tested.

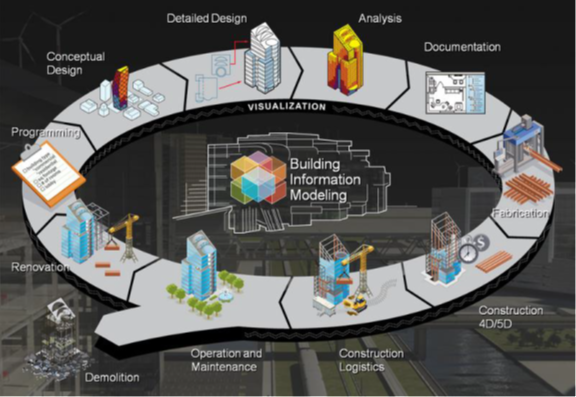

1. Building information modeling (BIM)

BIM is the process of creating and managing information on the construction process within the project lifecycle. The technology has been around for some time, but technological advancements are changing its scope and applicability. The 3D modeling software in BIM enables the construction managers to see the plan, design, and construction from a higher perspective. BIM has also enabled the contractors to examine the concrete projects' scope as opposed to 2-D technology. Therefore, building information modeling is advantageous because it reduces mistakes and delays, minimizes waste, and improves the supply chain.

Image courtesy of Autodesk

2. Drone technology

Drone technology is one of the latest trends in concrete technology that has been widely adopted. Previously, the contractors could not survey the construction process entirely since they were limited. Some relied on the airplanes to give an aerial perspective of the site, which was too expensive and escalated construction costs. Drones have provided a more cheap and reliable method of inspecting sites from an aerial view, and the time taken to complete inspection is far less than the previous methods. The drones have benefited the construction managers as it helps optimize layouts through digitation. With drone technology, there is increasing visibility to note impending problems and initiate speedy mitigation measures. Drones also ensure that the projects stay on track.

Image courtesy of commercial UAV news

3. Self-healing concrete

Self-healing concrete has been adopted in the current trend to mitigate problems after constructing concrete structures, including bends, leaks, and cracks. These types of concrete contain limestone producing bacteria that repair cracks in concrete. The limestone producing bacteria can also repair mortars for existing structures.

Through capillarity, self-healing products allow water particles to penetrate cracks, which then soaks and hydrate cement causing it to expand and fill the cracks. However, self-healing is applicable for cracks up to 0.1mm, and above that requires other constructive works.

Self-healing concrete is prepared by direct application and by encapsulation in lightweight concrete. This concrete technology is beneficial since it improves the strength of concrete, reduces permeability, reduces maintenance and repair, reduces corrosion, and increases

Concrete Technology resistance to freeze-thaw attack in concrete. However, the cost of self-healing concrete is two times more than conventional concrete, and it also requires skilled labor for implementation.

4. Graphic concrete

Graphic concrete is a technology in concrete works adopted by architects and the precast concrete industry to manufacture high quality patterned concrete surfaces. These surfaces are then applied to industrially produced floors and walls. Samuli invented the technology Naamanka and have been a proven technology in the precast concrete industry.

According to the CEO of graphic concrete LTD, graphic concrete offers versatility in creating distinctive imagery to precast concrete surfaces. The technology involves establishing a visual idea on a particular membrane and translating it to the precast concrete surface. The membrane can be disposed of and molded in any desired form or shape. With this innovative technology, various concrete patterned surfaces can be created, and color pigments customized to enhance the design.

Image courtesy of graphic concrete LTD

5. Ultra-High-Performance Concrete (UHPC)

UHPC is a new trend in concrete technology that contains newly made ingredients, including fiber. UPHC retains 80% of what makes up the traditional concrete. The fibers used vary in strength from polyester to stainless steel, and each component delivers additional strength and durability to the final product.

Compared with traditional concrete, which has a lifespan of 15-25 years, UHPC has a lifespan of more than 75 years. Due to superior quality and government support, the adoption of UHPC is increasing widely. The US federal government has advocated its use in bridges and highways. Also, the global market of UHPC is expected to grow at a rate of 6.92 % between 2017 to 2023.

Bottom line

Contemporary trends in concrete technology have now taken shape in the market, and the construction industry is being revolutionized. From the drones that enhance aerial view monitoring of the construction operations to self-healing concrete that enhances durability and permeability in concrete, the latest trends have transformed concrete technology. Improved concrete performance has led to the development of structures that stand the test of time. Concrete technology will still be enhanced to provide more efficiency and durability.